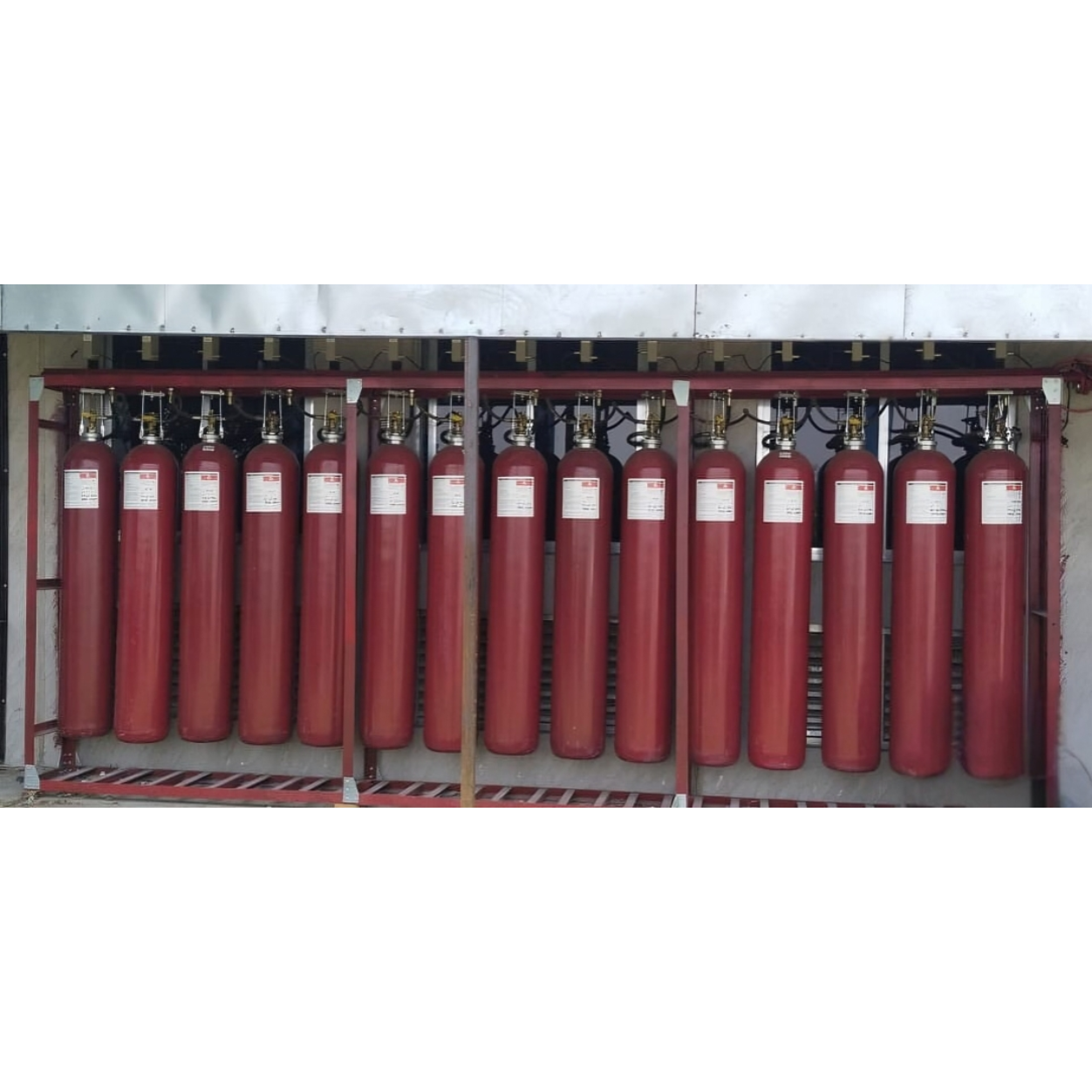

CO2 Fire Suppression System: Because of its ability to quickly displace oxygen, carbon dioxide (CO2) gas has long been used as a fire suppressor in a variety of safety and industrial applications. While some suppression agents like water reduce the heat of fire, a CO2 fire suppression system displaces the oxygen to suppress the fire. A CO2 fire suppression system works by releasing carbon dioxide gas into a protected area to displace oxygen, which is essential for combustion. When a fire is detected, the system activates and discharges CO2 rapidly, reducing the oxygen concentration to a level that can no longer sustain the fire. Carbon dioxide is non-conductive and does not leave behind any residue, making it particularly effective for use in areas with sensitive equipment, such as data centers, power plants, and marine vessels. Upon fire detection, the control panel triggers the release of CO2 gas from the storage cylinders through a network of piping and nozzles, distributing the gas evenly throughout the area. At the same time an alarm is sounded to warn any occupants to leave the room immediately. Due to its rapid and effective suppression properties, CO2 systems are ideal for environments where minimizing fire damage and ensuring continuity of operations are crucial. However, safety measures must be in place, as CO2 is hazardous to humans at high concentrations and CO2 levels above 5% are an asphyxiant. Key Components of a CO2 Fire Suppression System The key components of a CO2 fire suppression system include CO2 storage cylinders, discharge nozzles, piping networks, fire detectors, and a control panel. The CO2 storage cylinders are designed to store carbon dioxide under high pressure until it is needed for fire suppression. These cylinders are equipped with release valves that activate when the system detects a fire. The carbon dioxide then travels through a network of piping to reach strategically placed discharge nozzles, which ensure that the CO2 is evenly distributed throughout the protected area to extinguish the fire. Fire detectors and the control panel are crucial components for monitoring and activating the system. The detectors, which can be smoke, heat, or flame sensors, continuously monitor the protected area for signs of a fire. Additional components like manual pull stations and warning alarms may also be present to allow manual activation and to alert personnel to evacuate the area before CO2 is discharged. Each component plays a vital role in ensuring the effectiveness and safety of the fire suppression process. CO2 fire suppression systems are commonly used across a wide variety of applications where rapid fire control is crucial, and water-based systems may cause damage to equipment or materials. These systems are especially common in facilities with valuable or sensitive assets, as CO2 does not leave any residue after discharge. Below are some key industries and environments where CO2 fire suppression systems are commonly deployed: Data Centers and Server Rooms: Protecting sensitive electronic equipment from both fire damage and water damage is critical in data centers, making CO2 an ideal fire suppression choice. Power Generation Facilities: Electrical hazards in power plants, such as turbines and transformers, benefit from the non-conductive properties of CO2. Marine Vessels: CO2 systems are used in engine rooms and cargo holds of ships, where space is confined and other suppression agents may be impractical. Industrial Manufacturing: Facilities with flammable liquids or combustible materials, such as chemical plants, often use CO2 systems to quickly suppress fires without contaminating products. Automotive Paint Booths: The highly flammable chemicals used in paint booths require fast-acting fire suppression that will not damage the painted surfaces or cause an unsafe environment. These specialized applications highlight the flexibility and effectiveness of CO2 fire suppression systems in protecting valuable assets, preventing equipment downtime, and minimizing fire-related damage. One particular partner, Fire Systems, Inc. also uses CO2 systems primarily in rooms that hold printing presses or chemical rooms according to Geoff Zimbelman at Fire Systems, Inc. 'CO2 flooding systems require 34% CO2 concentration to extinguish a normal fire, while some chemical fires require 65-70%.' Benefits of Using CO2 Fire Suppression Systems CO2 fire suppression systems offer several benefits, making them a popular choice for environments where traditional fire suppression methods may not be suitable. One of the key advantages is that carbon dioxide is a clean, residue-free extinguishing agent. Unlike water or foam-based systems, CO2 leaves no trace after discharge, which is crucial for protecting sensitive electronics, valuable equipment, and materials that could be damaged by water. This makes CO2 ideal for data centers, power plants, and manufacturing facilities that handle delicate machinery or valuable assets. CO2 has also been a proven gaseous fire suppression agent as far back as the beginning of the 1960's. Another benefit of CO2 fire suppression systems is their rapid fire suppression capability. CO2 works by displacing oxygen and reducing it to a level where combustion cannot be sustained, effectively and quickly extinguishing a fire. The system's ability to respond rapidly minimizes the spread of fire and potential damage, thereby reducing downtime and repair costs. Additionally, CO2 is non-conductive, making it safe for use in electrical environments where other fire suppression agents might pose a hazard. Additionally, CO2 is effective on a wide range of flammable and combustible materials, and is approved for suppression of Class A, B and C hazards. Comparing CO2 Fire Suppression to Other Fire Protection Methods When comparing CO2 fire suppression systems to other fire protection methods, it’s important to consider the specific needs of the environment being protected. Unlike water-based systems, such as sprinklers, CO2 fire suppression does not leave behind any residue or water damage, making it ideal for areas containing sensitive electronic equipment or valuable materials that could be damaged by water. This makes CO2 systems preferable in data centers, power plants, and environments where avoiding collateral damage is essential. Compared to chemical clean agent systems like FM-200 or Novec 1230, CO2 fire suppression systems are more cost-effective and offer rapid extinguishing capabilities without leaving any residue. However, CO2 systems can be hazardous to humans at high concentrations, which makes them better suited for unoccupied areas or spaces where appropriate safety measures can be enforced. On the other hand, sprinkler systems and clean agents are safer for occupied areas but may not offer the same level of fire suppression speed and efficiency as CO2. By understanding these differences, businesses can make informed decisions about the most suitable fire protection method based on their specific requirements. What NFPA code is the standard for CO2 extinguishing systems? If you utilize CO2 as your suppression agent then you'll be required to meet NFPA 12 standards. NFPA 12 details the requirements for testing a CO2 suppression system including the points in the room, timing requirements, and the necessary concentration thresholds. Typically, industrial suppression systems utilize banks of high pressure CO2 cylinders to release CO2 in a 100% concentration to displace the oxygen as quickly as possible. These standards require full discharge tests and evacuation plans in order to ensure that the air be tested for normal levels before personnel can return to work. Safety considerations for CO2 fire suppression systems are essential, as carbon dioxide can be hazardous to humans at high concentrations. CO2 works by displacing oxygen, which effectively suppresses a fire but can also pose significant risks to personnel in the protected area. Therefore, CO2 fire suppression systems are generally recommended for unoccupied spaces or areas where stringent safety protocols can be implemented to ensure human safety. It is crucial that all personnel are trained in safety procedures, including evacuation protocols, to avoid exposure to CO2 during discharge. Key safety measures include: Warning Alarms: Audible and visual alarms are installed to alert individuals before CO2 is discharged, ensuring they have time to evacuate. Manual Pull Stations and Abort Switches: These allow personnel to delay or abort system activation if people are still present in the protected area. Proper Ventilation: Effective ventilation should be in place to quickly dissipate CO2 after discharge, allowing for safe reentry. Training for Personnel: Regular training in safety procedures, including evacuation plans and system operation, is essential to ensure everyone knows how to respond in an emergency. These safety considerations help ensure that while the CO2 fire suppression system effectively controls fires, it also minimizes the risk to human health, making it a reliable choice for fire protection in controlled environments.

Chat with us on WhatsApp

×

This is your website preview.

Currently it only shows your basic business info. Start adding relevant business details such as description, images and products or services to gain your customers attention by using Boost 360 android app / iOS App / web portal.

CO2 Fire Suppression System: Because of its ab...

2025-04-29T05:34:21

CO2 Fire Suppression System: Because of its ability to quickly displace oxygen, carbon dioxide (CO2) gas has long been used as a fire suppressor in a variety of safety and industrial applications. While some suppression agents like water reduce the heat of fire, a CO2 fire suppression system displaces the oxygen to suppress the fire. A CO2 fire suppression system works by releasing carbon dioxide gas into a protected area to displace oxygen, which is essential for combustion. When a fire is detected, the system activates and discharges CO2 rapidly, reducing the oxygen concentration to a level that can no longer sustain the fire. Carbon dioxide is non-conductive and does not leave behind any residue, making it particularly effective for use in areas with sensitive equipment, such as data centers, power plants, and marine vessels. Upon fire detection, the control panel triggers the release of CO2 gas from the storage cylinders through a network of piping and nozzles, distributing the gas evenly throughout the area. At the same time an alarm is sounded to warn any occupants to leave the room immediately. Due to its rapid and effective suppression properties, CO2 systems are ideal for environments where minimizing fire damage and ensuring continuity of operations are crucial. However, safety measures must be in place, as CO2 is hazardous to humans at high concentrations and CO2 levels above 5% are an asphyxiant. Key Components of a CO2 Fire Suppression System The key components of a CO2 fire suppression system include CO2 storage cylinders, discharge nozzles, piping networks, fire detectors, and a control panel. The CO2 storage cylinders are designed to store carbon dioxide under high pressure until it is needed for fire suppression. These cylinders are equipped with release valves that activate when the system detects a fire. The carbon dioxide then travels through a network of piping to reach strategically placed discharge nozzles, which ensure that the CO2 is evenly distributed throughout the protected area to extinguish the fire. Fire detectors and the control panel are crucial components for monitoring and activating the system. The detectors, which can be smoke, heat, or flame sensors, continuously monitor the protected area for signs of a fire. Additional components like manual pull stations and warning alarms may also be present to allow manual activation and to alert personnel to evacuate the area before CO2 is discharged. Each component plays a vital role in ensuring the effectiveness and safety of the fire suppression process. CO2 fire suppression systems are commonly used across a wide variety of applications where rapid fire control is crucial, and water-based systems may cause damage to equipment or materials. These systems are especially common in facilities with valuable or sensitive assets, as CO2 does not leave any residue after discharge. Below are some key industries and environments where CO2 fire suppression systems are commonly deployed: Data Centers and Server Rooms: Protecting sensitive electronic equipment from both fire damage and water damage is critical in data centers, making CO2 an ideal fire suppression choice. Power Generation Facilities: Electrical hazards in power plants, such as turbines and transformers, benefit from the non-conductive properties of CO2. Marine Vessels: CO2 systems are used in engine rooms and cargo holds of ships, where space is confined and other suppression agents may be impractical. Industrial Manufacturing: Facilities with flammable liquids or combustible materials, such as chemical plants, often use CO2 systems to quickly suppress fires without contaminating products. Automotive Paint Booths: The highly flammable chemicals used in paint booths require fast-acting fire suppression that will not damage the painted surfaces or cause an unsafe environment. These specialized applications highlight the flexibility and effectiveness of CO2 fire suppression systems in protecting valuable assets, preventing equipment downtime, and minimizing fire-related damage. One particular partner, Fire Systems, Inc. also uses CO2 systems primarily in rooms that hold printing presses or chemical rooms according to Geoff Zimbelman at Fire Systems, Inc. 'CO2 flooding systems require 34% CO2 concentration to extinguish a normal fire, while some chemical fires require 65-70%.' Benefits of Using CO2 Fire Suppression Systems CO2 fire suppression systems offer several benefits, making them a popular choice for environments where traditional fire suppression methods may not be suitable. One of the key advantages is that carbon dioxide is a clean, residue-free extinguishing agent. Unlike water or foam-based systems, CO2 leaves no trace after discharge, which is crucial for protecting sensitive electronics, valuable equipment, and materials that could be damaged by water. This makes CO2 ideal for data centers, power plants, and manufacturing facilities that handle delicate machinery or valuable assets. CO2 has also been a proven gaseous fire suppression agent as far back as the beginning of the 1960's. Another benefit of CO2 fire suppression systems is their rapid fire suppression capability. CO2 works by displacing oxygen and reducing it to a level where combustion cannot be sustained, effectively and quickly extinguishing a fire. The system's ability to respond rapidly minimizes the spread of fire and potential damage, thereby reducing downtime and repair costs. Additionally, CO2 is non-conductive, making it safe for use in electrical environments where other fire suppression agents might pose a hazard. Additionally, CO2 is effective on a wide range of flammable and combustible materials, and is approved for suppression of Class A, B and C hazards. Comparing CO2 Fire Suppression to Other Fire Protection Methods When comparing CO2 fire suppression systems to other fire protection methods, it’s important to consider the specific needs of the environment being protected. Unlike water-based systems, such as sprinklers, CO2 fire suppression does not leave behind any residue or water damage, making it ideal for areas containing sensitive electronic equipment or valuable materials that could be damaged by water. This makes CO2 systems preferable in data centers, power plants, and environments where avoiding collateral damage is essential. Compared to chemical clean agent systems like FM-200 or Novec 1230, CO2 fire suppression systems are more cost-effective and offer rapid extinguishing capabilities without leaving any residue. However, CO2 systems can be hazardous to humans at high concentrations, which makes them better suited for unoccupied areas or spaces where appropriate safety measures can be enforced. On the other hand, sprinkler systems and clean agents are safer for occupied areas but may not offer the same level of fire suppression speed and efficiency as CO2. By understanding these differences, businesses can make informed decisions about the most suitable fire protection method based on their specific requirements. What NFPA code is the standard for CO2 extinguishing systems? If you utilize CO2 as your suppression agent then you'll be required to meet NFPA 12 standards. NFPA 12 details the requirements for testing a CO2 suppression system including the points in the room, timing requirements, and the necessary concentration thresholds. Typically, industrial suppression systems utilize banks of high pressure CO2 cylinders to release CO2 in a 100% concentration to displace the oxygen as quickly as possible. These standards require full discharge tests and evacuation plans in order to ensure that the air be tested for normal levels before personnel can return to work. Safety considerations for CO2 fire suppression systems are essential, as carbon dioxide can be hazardous to humans at high concentrations. CO2 works by displacing oxygen, which effectively suppresses a fire but can also pose significant risks to personnel in the protected area. Therefore, CO2 fire suppression systems are generally recommended for unoccupied spaces or areas where stringent safety protocols can be implemented to ensure human safety. It is crucial that all personnel are trained in safety procedures, including evacuation protocols, to avoid exposure to CO2 during discharge. Key safety measures include: Warning Alarms: Audible and visual alarms are installed to alert individuals before CO2 is discharged, ensuring they have time to evacuate. Manual Pull Stations and Abort Switches: These allow personnel to delay or abort system activation if people are still present in the protected area. Proper Ventilation: Effective ventilation should be in place to quickly dissipate CO2 after discharge, allowing for safe reentry. Training for Personnel: Regular training in safety procedures, including evacuation plans and system operation, is essential to ensure everyone knows how to respond in an emergency. These safety considerations help ensure that while the CO2 fire suppression system effectively controls fires, it also minimizes the risk to human health, making it a reliable choice for fire protection in controlled environments.

2025-04-29T05:34:21

Keywords

- 100 concentration

- discharged ensuring

- oxygen concentration

- displace oxygen

- essential compared

- controlled environments

- electrical environments

- occupied areas

- unoccupied areas

- discharge allowing

- unoccupied spaces

- specific requirements

- reducing downtime

- manufacturing facilities

- unsafe environment

- transformers benefit

- wide variety

- alert personnel

- smoke heat

- discharge nozzles

- valuable materials

- combustible materials

- residue making

- displacing oxygen

- chemical rooms

- engine rooms

- nonconductive properties

- release valves

- ensuring continuity

- protected area

- crucial components

- release co2

- systems ability

- water reduce

- reliable choice

- alert individuals

- avoid exposure

- generally recommended

- effectively suppresses

- normal levels

- evacuation plans

- nfpa code

- differences businesses

- wide range

- sustained effectively

- popular choice

- geoff zimbelman

- painted surfaces

- chemical plants

- flammable liquids

- cargo holds

- power plants

- vital role

- component plays

- evenly distributed

- reach strategically

- high pressure

- high concentrations

- gas evenly

- nozzles distributing

- marine vessels

- longer sustain

- industrial applications

- water damage

- utilize co2

- co2 levels

- co2 gas

- nonconductive making

- safety procedures

- safety measures

- normal fire

- fire detection

- fire suppressor

- system operation

- system detects

- system activates

- potential damage

- suppression agent

- clean agents

- key advantages

- key industries

- waterbased systems

- visual alarms

- sensitive equipment

- co2 systems

- fire damage

- benefits making

- fire suppression

- fire systems

- abort switches

- evacuation protocols

- storage cylinders

- suppression agents

- safety considerations

- quickly extinguishing

- key components

- carbon dioxide

- fire protection

- sensitive assets

- warning alarms

- control panel

- manual activation

- makes co2 ideal

- fire fire detectors

- water damage making

- co2 suppression system

- ensure human safety

- valuable assets co2

- co2 storage cylinders

- fire suppression agents

- rapid fire control

- co2 extinguishing systems

- fire carbon dioxide

- respond rapidly minimizes

- abort system activation

- quickly suppress fires

- quickly dissipate co2

- sensitive electronic equipment

- co2 systems primarily

- minimizing fire damage

- fire suppression speed

- partner fire systems

- personnel regular training

- stringent safety protocols

- work safety considerations

- fire additional components

- asphyxiant key components

- store carbon dioxide

- fire protection methods

- warning alarms audible

- control panel triggers

- safe reentry training

- pose significant risks

- room timing requirements

- specialized applications highlight

- highly flammable chemicals

- hazard additionally co2

- avoiding collateral damage

- minimizing firerelated damage

- hand sprinkler systems

- human health making

- manual pull stations

- make informed decisions

- handle delicate machinery

- hold printing presses

- room immediately due

Search on this site

Have any question or need any business consultation?

Have any question or need any business consultation?

Contact UsAsha Enterprise India

Submit Your Enquiry